Ancillary equipment

Diaphragm Bump in-feed, water heater, mixer tank, Ribbon printer,take-away conveyors, checkweighers, recycling device

Feature

Bag length, filling volume, packing speed, and more can be set on touch screen, easy to operate,servo driven system, ensuring of accurate bag length and filling dose.

Automatic in forming, measuring, filing, sealing, cutting, counting, lot code printing.

Film material

Polyester/polyethylene, polyester/foil/polyethylene, polyester/akiminium/polyethylene,Paper/polyethylene, Nylon and other heat sealable laminated film structures.

film material requirement: thickness between 40 micron and 80 micron, roll core no more than 75mm, roll diameter no more than 320mm

Application

Applicable in food, medical, chemical industries, for semi-liquid or paste products, such as honey,sauce, vegetable oil, water, wine, soy sauce, vineger, detergent, sanitizer, disinfecatant, shampoo etc.

Specification

| Model | YJ100 | YJ200 | YJ300 |

| bag length | 50-150 mm | 50-150 mm | 50-300 mm |

| bag width | 25-120 mm | 25-120 mm | 70-190 mm |

| film width | 50-260 mm | 50-260 mm | 140-400 mm |

| bag volume | 5-100 ml | 50-300 ml | 100-1000 ML |

| packing speed | 30-50 bpm | 25-40 bpm | 20-30 bpm |

| power supply | 220V/AC 50Hz 1.6Kw | 220V/AC 50Hz 1.6Kw | 220V/AC 50Hz 1.8Kw |

| machine dimension | 760 × 1380 × 1700mm | 760 × 1380 × 1700mm | 900 × 1800 ×2040mm |

| machine weight | 300Kg | 300Kg | 500Kg |

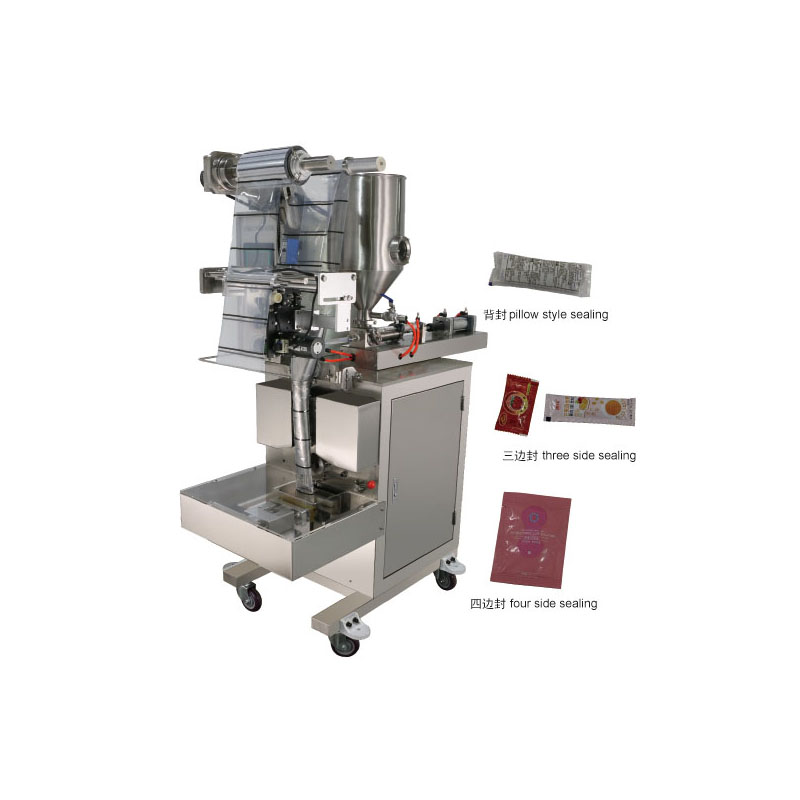

| sealing style | pillow style, three, four side seal | ||

| air requirments | 0.8Mpa, 150L/min | 0.8Mpa, 180L/min | 0.8Mpa, 250L/min |